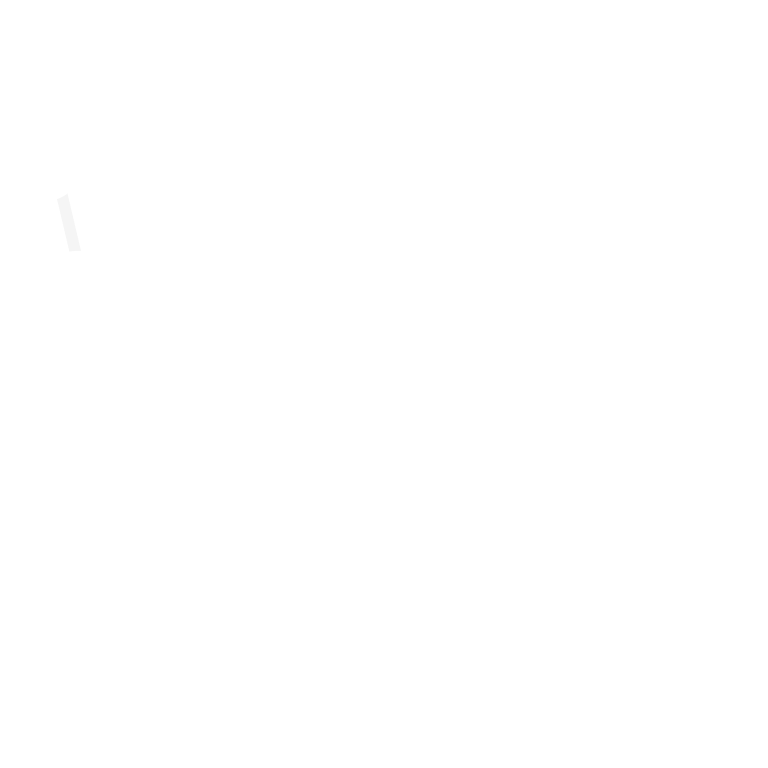

All plastics are made from lots of small units stuck together like beads on a necklace. There are many types of small units, so there are many types of plastic. The units for almost all plastics come from fossil fuels, but an increasing number come from plants.

If you could look closely at some plastic, you’d see that it’s made of lots of very long chains. The chains are made up of lots of small pieces stuck together. You can think of them like beads on a necklace. Often, each bead is the same.

There are lots of different types of bead. That’s one reason why some plastics look and behave differently to others. Plastic isn’t just one material, it’s lots of different materials. They all share this necklace-like structure though.

The starting material for most plastic is petroleum (crude oil) or gas. This is used to make the small units, which then react with each other and stick together to make a long string. Lots of long strings bunch together to make a plastic.

The long strings in plastics can either be all tangled up, or they can be held together in an ordered structure. Additionally, other things can be added, such as chemicals that make the plastic coloured, protect it from light and heat, or make it more flexible.

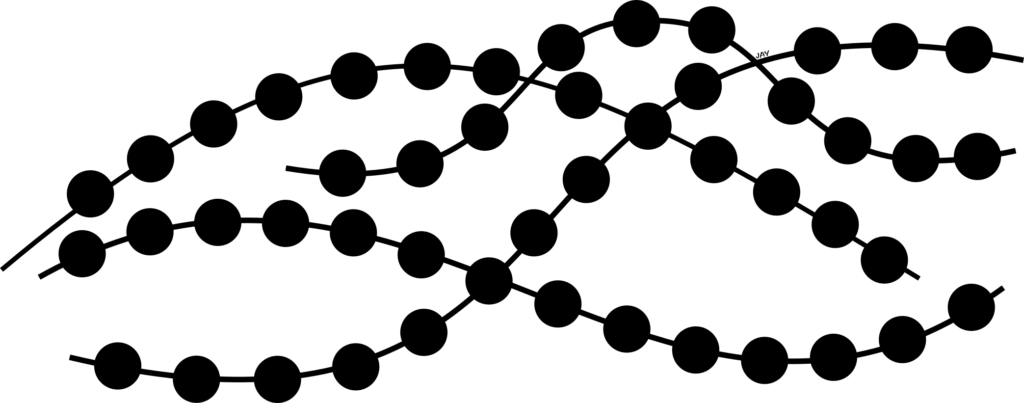

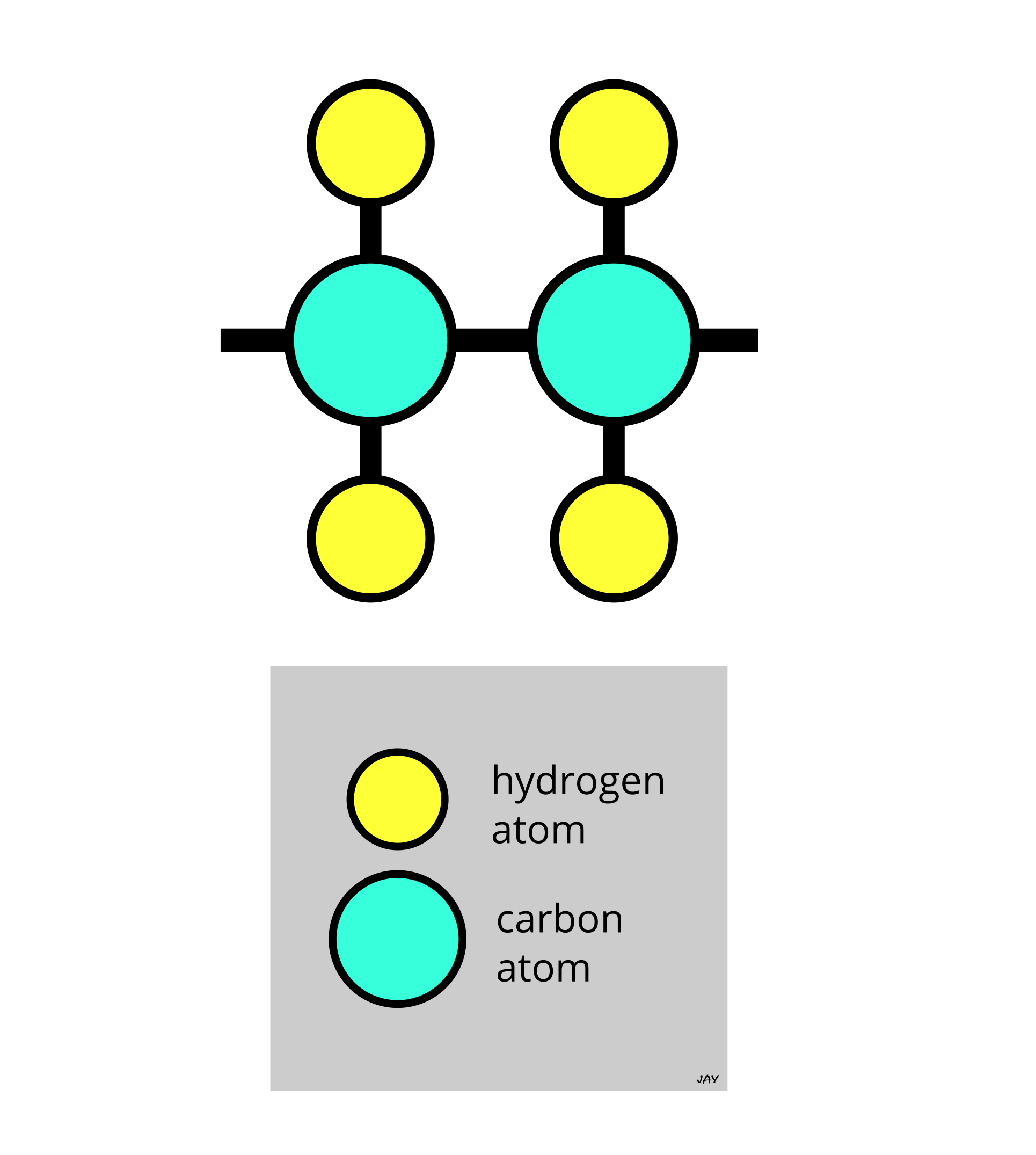

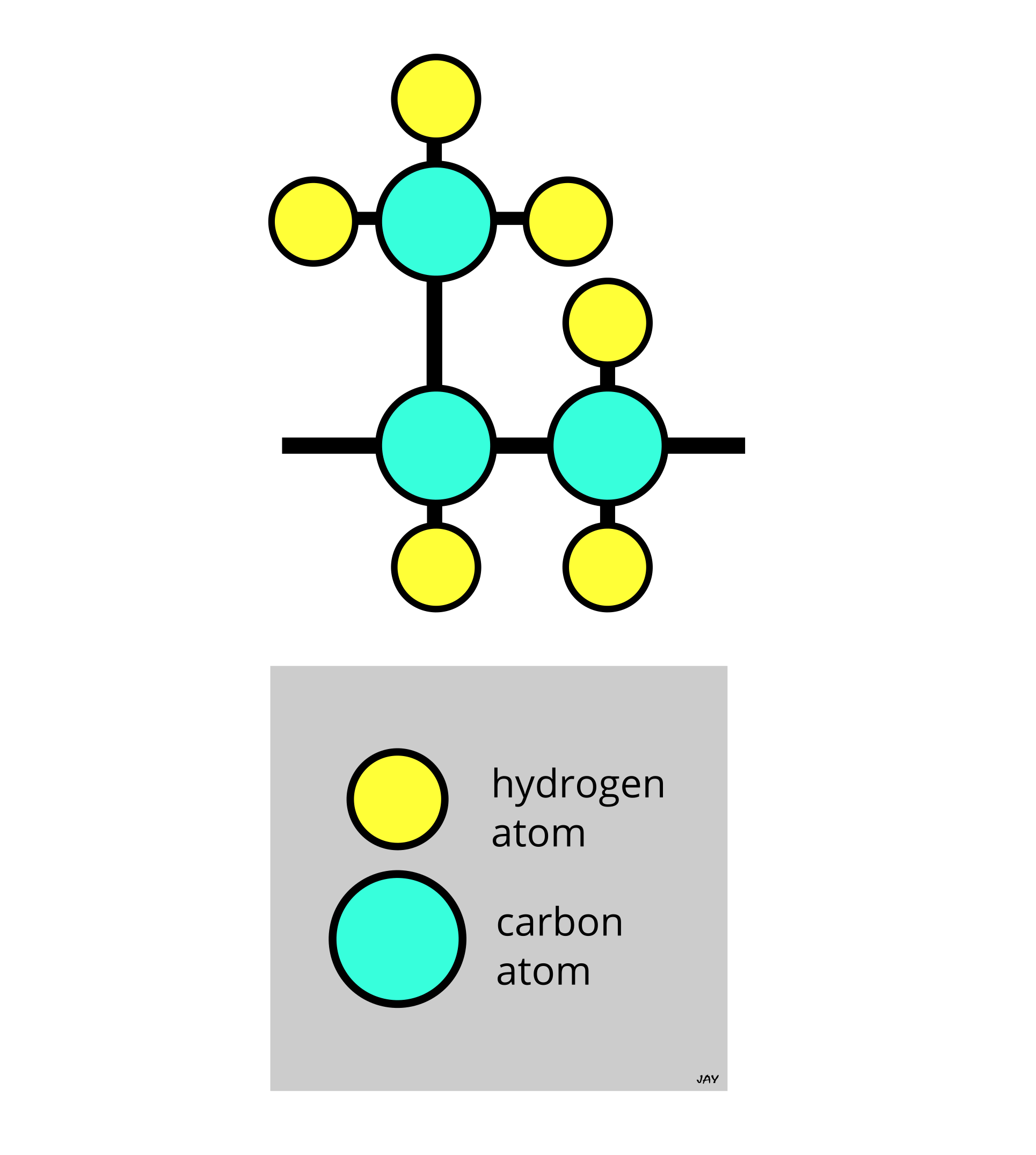

Here’s more info about the most common plastics. I’ve also drawn you one of the small units for each type of plastic. Each one acts as a bead in the necklace for that type of plastic.

What is polythene?

Polythene is the most common plastic in the world and you’ll probably meet it every day, maybe as a carrier bag, squeezy bottle, or some other packaging. Over 100 million tonnes of it are made each year. For reference, one million tonnes is about the same as one million small cars.

The more scientific name for polythene is polyethene, or polyethylene. That’s because it’s made of units called ethene (sometimes called ethylene), and ‘poly’ is the term we use to mean ‘many’. So ‘polyethene’ literally means ‘lots of ethene’. Its common name, polythene, is easier to say though, isn’t it.

Polythene comes in two forms: LDPE, which is low density (light) polyethylene, and HDPE, which is high density (heavy) polyethylene. They have very simple structures compared to some other plastics. Their long chains are made of units that only contain carbon and hydrogen atoms.

LDPE and HDPE have some differences that make each one suited to different uses. LDPE has some branches in its structure, like a tree. The branches cause the molecules to sit further apart from each other, like the trees in a forest. This makes LDPE lighter (i.e. lower density) than HDPE. It also causes LDPE to soften at lower temperatures than HDPE.

So, LDPE is more commonly used for things that need to be light and bendy, like six pack rings, whereas HDPE can be picked for things that need to be strong, like plastic furniture. There’s a lot of overlap though: both LDPE and HDPE are common choices for plastic bags. In general, thin plastic bags are made from HDPE and thicker ones, like rubbish bags, are made from LDPE.

What is polypropylene?

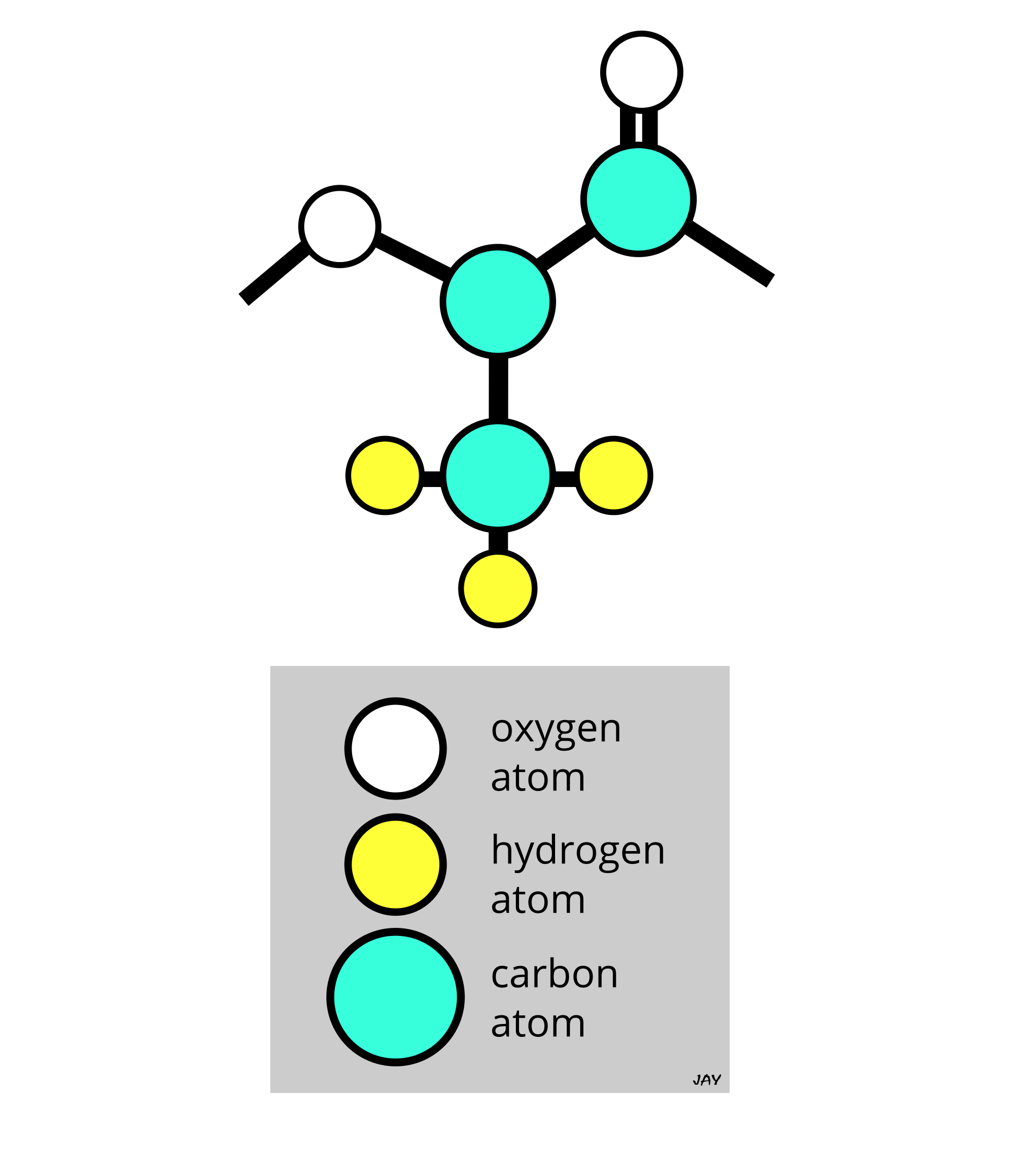

Polypropylene (PP) is the second most common plastic in the world. About 70 million tonnes were made in 2015, which is the most recent comprehensive data I could find. The global trend for plastic production is an increasing one, though. PP is also often used to make disposable face masks and other PPE that will probably be very familiar these days, so it’s likely that PP suppliers have had a few good years recently.

The small units of PP are made from only carbon and hydrogen atoms. That makes it very similar to polythene. Where polythene is made of many ethene units, polypropylene is made of lots of propene (or propylene) units. The two units are different shapes, as you can see in the diagrams. This gives PP a slightly more branched structure compared to polythene, which affects the properties of the plastic. For example, PP is generally lighter than polythene, depending on how it is made.

PP is a very versatile and inexpensive plastic. Its uses go beyond face masks to include packaging, carpets, wet wipes, furniture, car parts… lots more. It might seem odd that this very different collection of things can be made from the same material. However, the properties of PP can be made to vary a lot by using different production methods. This allows a single material to suit many different end uses.

Lots of other plastics also have very versatile properties. This means that the uses of different plastics often overlap with one another, which can make it quite difficult to determine which plastic has been used for what purpose.

What is PVC?

PVC is properly known as polyvinyl chloride. It has been an enabler of squeaky clothes since the 1960s. About 40 million tonnes of it are made each year. PVC comes in two types: bendy and non-bendy. The bendy type is used for things like clothes, clingfilm, and cables. The non-bendy type is used for things like doors and window frames.

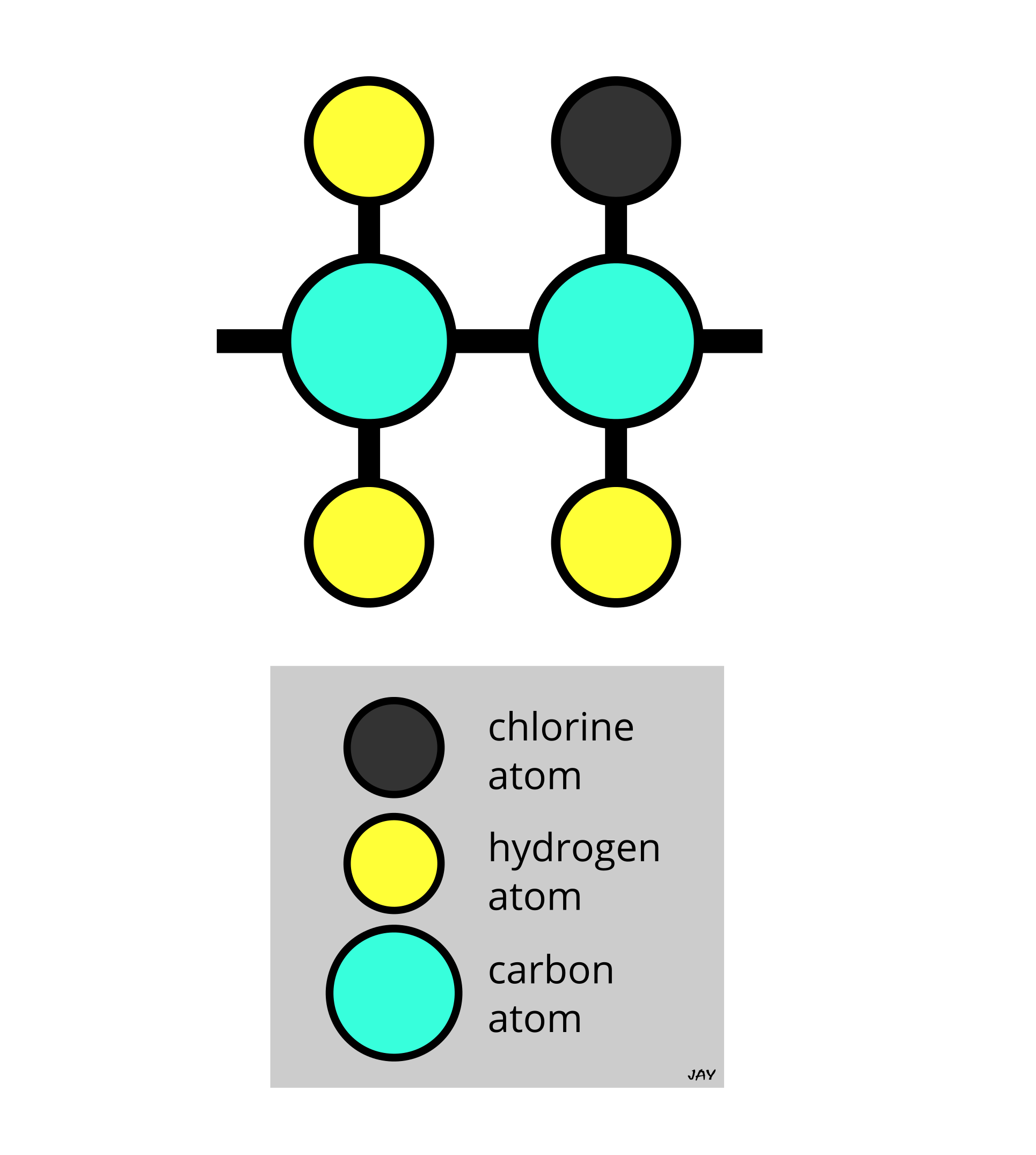

The structure of PVC is pretty similar to polythene again. This time, the only difference is that it contains some chlorine, which replaces some of the hydrogen. You can see this reflected in its full name, polyvinyl chloride, where the ‘chloride’ part refers to the chlorine in the small unit.

You might be able to see from the diagram that only one of the four hydrogen atoms in each unit is replaced with a chlorine atom. This small difference is enough to produce a material with very different properties to polythene. The chlorine atoms cause the long molecules (‘strings’) to stick together more tightly. This makes a strong, rigid material that doesn’t bend. PVC is therefore useful for things that need to be strong, like doors and window frames.

So, what about bendy PVC then? This is made by adding something else to the structure of the plastic. Chemicals called plasticisers are added to PVC. These stop the long plastic strings from clinging onto each other so tightly, allowing the material to bend. Bendy PVC makes up most of the global demand for plasticisers. The strong version of PVC is called unplasticed PVC, which is commonly known as uPVC.

What is polyester?

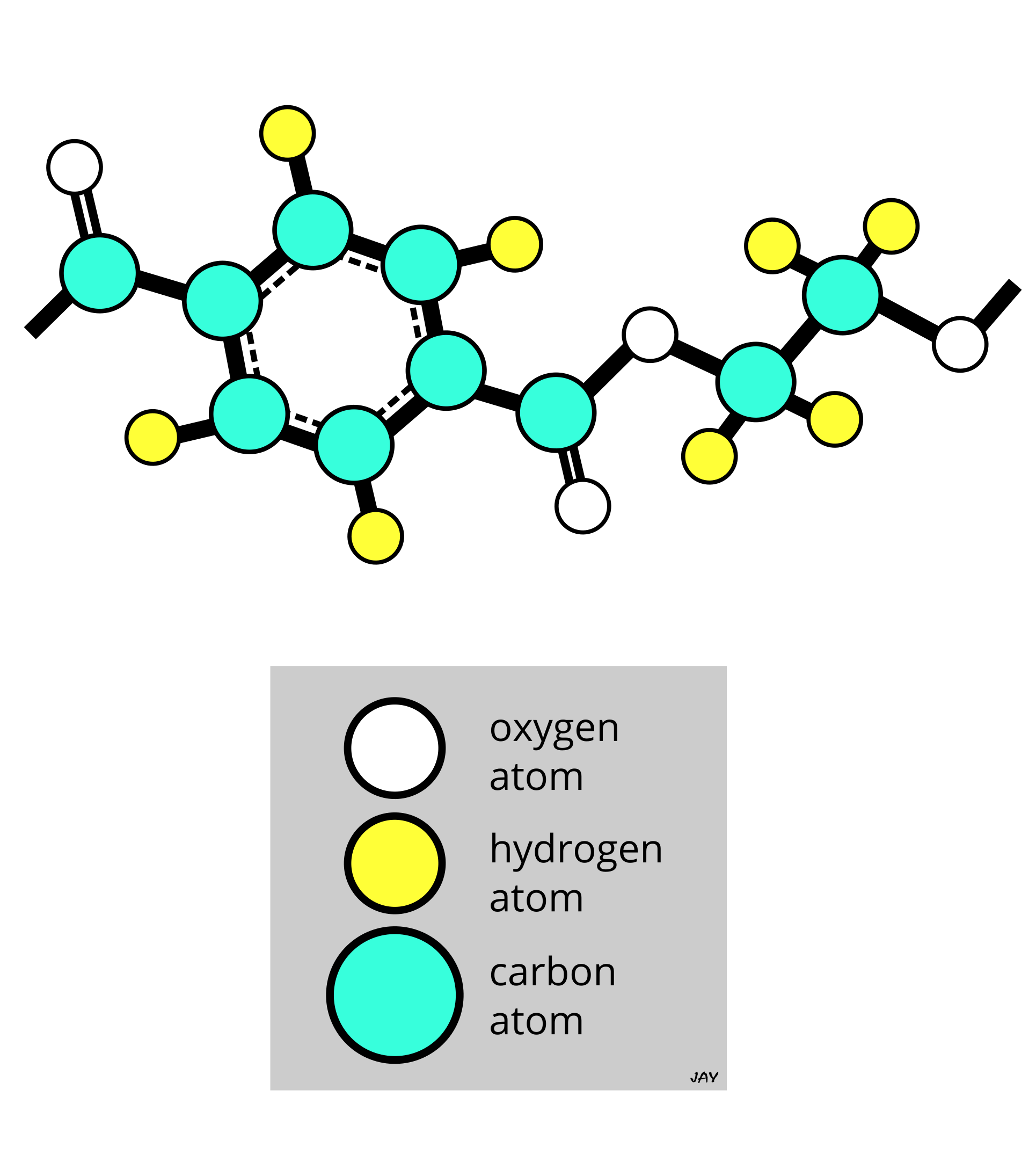

By now, you might have noticed that the proper name of plastics often begins with ‘poly’. Polyester is no different. You can probably guess from above that it’s made up of lots of units called esters. Esters are actually a family of chemicals, so there are technically a few different types of polyester. The most common one has the catchy name polyethylene terephthalate. It’s usually just known as PET.

Like polythene, PET is made of carbon and hydrogen, but it also has some oxygen added. If you’re confused about seeing oxygen inside a material rather than in the air, don’t be alarmed. Lots of things contain oxygen. It’s often stuck together with other types of atoms so that you’d never know it was there. In PET, the oxygen is bonded with carbon and hydrogen to make an elaborate structure that took me ages to draw.

As with other plastics, PET has versatile properties, and it can be used to make things that don’t seem very similar. It can be moulded to make plastic bottles (shampoo, mineral water, etc). It can also be spun into fibres to make clothes, where it’s known as polyester.

Note that other types of plastic can also be spun into fibres. These include nylon, acrylic, and polypropylene (hi again!). Fishing nets are often made of nylon.

Where do plastics come from?

There’s clearly a lot of variety in the small units used to make different plastics. I’ve covered the four most common ones above, but there are many others including polystyrene, elastane (lycra), and synthetic rubber. The units in these are different again. However, despite their differences, plastics are essentially made from different arrangements of carbon and hydrogen atoms, with other types of atom joining the party where necessary.

You may already know that most plastics come from fossil fuels like crude oil or gas. That’s because fossil fuels are a good source of the carbon and hydrogen atoms necessary to make plastics.

However, you can also make plastics from plants like maize/corn and sugarcane. An example of this is a plastic called PLA (polylactic acid), which is one of the most common types of plant-based plastics. Its small units are made from carbon, hydrogen and oxygen, like PET/polyester. Long strings of PLA bundle together to make a material that looks and behaves in a similar way to other plastics, so it is sometimes used in place of those.

I couldn’t find a usable picture of something made from PLA, so I took one of my rocktopus, which was made on a 3D printer using PLA filament.

Plastics made using renewable materials such as plants are sometimes called bioplastics. This might suggest that they are more environmentally friendly, but that isn’t necessarily the case because a lot depends on what happens when the plastic is no longer needed. I’ll leave that for another time.

Most of the plastic produced today is not plant-based plastic. Global production of PLA was around 190,000 tonnes in 2019, compared to around 400 million tonnes for conventional plastic in 2015. However, the global demand for plastics remains very high and is expected to increase still further over the coming decades. It’s likely that plant-based plastics will follow this same trend.